Simple Solutions to Everyday Problems.

CGEYE Engineering is a design firm with a focus on simplicity and attention to detail. Experienced in all aspects of product development in the consumer goods, medical, industrial, and fastening industries.

“People are the most important Asset” - founder of CGEYE

CGEYE Engineering is committed to setting itself apart from traditional design firms. Our dedicated team works tirelessly to ensure that client satisfaction remains our highest priority, drawing on years of engineering expertise and a deep passion for product development. Guided by our mission statement—“Putting people first”—we recognize that people are at the heart of every successful project, from design and testing to manufacturing, sales, and product use.

Portfolio

-

Aspiration Pump

Partnered with the client’s contract manufacturer to develop a patent‑pending, recyclable aspiration pump. The unit features a unique reservoir design that fully encloses the internal pump core, providing 360 degrees of reservoir capacity. CGEYE Engineering led the complete mechanical design from the ground up, managing vendor outsourcing, 3D models, assemblies, detailed drawings, material selection, and tolerance analysis. Throughout the process, CGEYE collaborated closely with the manufacturer’s electrical and systems engineering teams to ensure seamless integration and successful product development.

-

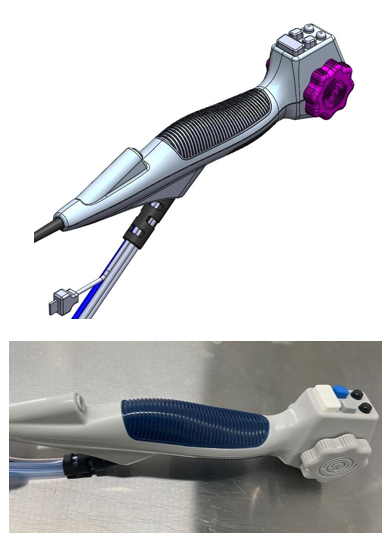

Evoendo Gastroscope

Collaborated with the client’s contract manufacturer to develop Version 2.0 of the single‑use Evoendo® Gastroscope. Conducted a comprehensive design‑for‑manufacture analysis to streamline assembly processes and enable efficient re‑work when required. Redesigned internal components and developed new outer housings to improve manufacturability and ease of assembly. Sourced vendors for all plastic components, produced detailed drawings, performed tolerance analysis, and engineered pilot line assembly fixtures and jigs to support initial production.

-

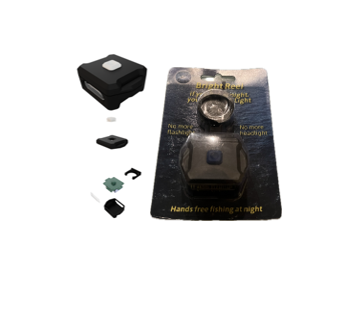

Fishing Bright Reel

Collaborated directly with the client to develop an innovative fishing reel light concept. Delivered initial 3D renderings and cost estimates to support feasibility analysis from a business perspective. Designed and built breadboard prototypes to validate proof of concept, followed by refined, functional prototypes for client testing and user feedback. Transitioned the project into full-scale production by coordinating with offshore manufacturing partners to oversee fabrication, assembly, and packaging.

-

Murphy Eye Punch Fixture

Designed and delivered a custom Murphy eye punch fixture tailored to client specifications. The fixture incorporated multiple punch sizes manufactured from high‑quality 17‑4 stainless steel, ensuring durability and performance. Engineered for efficiency, the design enabled quick changeovers between punches with minimal disassembly. A foot‑pedal mechanism was integrated to streamline cycling operations, enhancing ease of use and operator productivity.

-

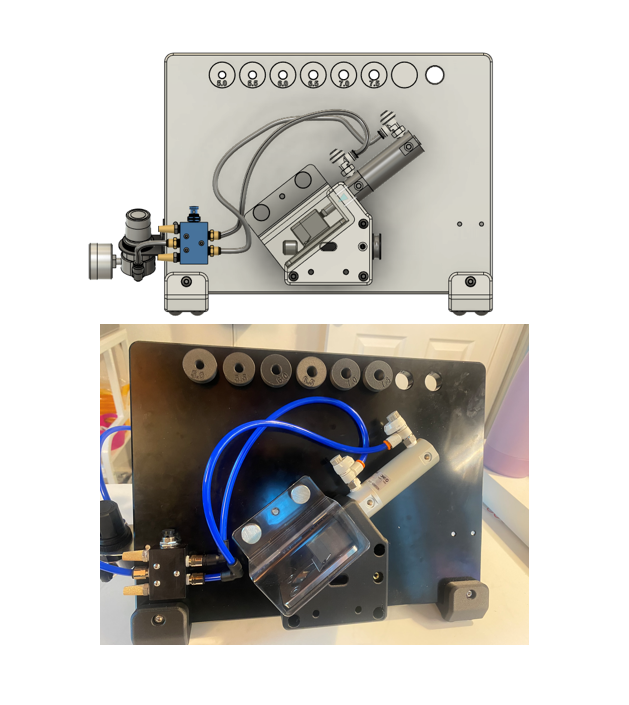

Tube Cut fixture

Developed a custom cutting fixture designed to accommodate tubing of various sizes per client specifications. Constructed using stainless steel and anodized aluminum components, complemented by select 3D‑printed parts for optimized functionality. Engineered for operator efficiency, the fixture features single‑button operation, an integrated safety shield, and a streamlined blade changeover system to minimize downtime and enhance workplace safety.

-

Custom Coiler Fixture

Developed a custom coiler fixture based on client specifications for medical device applications. The unit features a tailored user interface enabling operators to adjust parameters such as coil length and speed with ease. Powered by a single stepper motor, the system drives both the lead screw and spindle, with an integrated clutch allowing the spindle to be disengaged when required. This design provides flexibility, efficiency, and precise control throughout the coiling process.